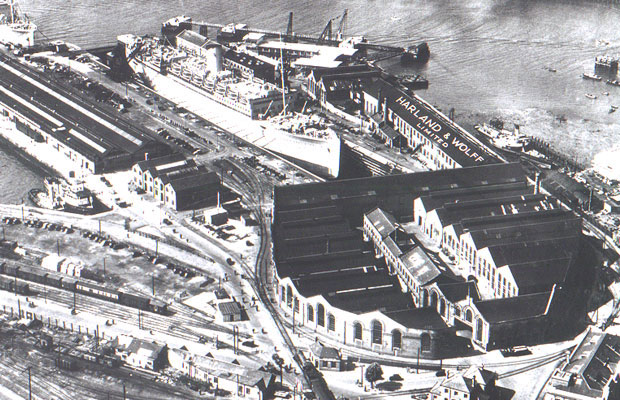

Shotblast and Paint Hall complex at Belfast

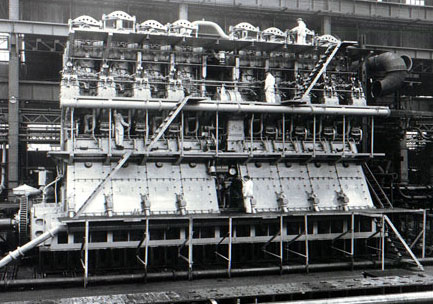

A shipyard's ability to construct massive

hull sections demands an equivalent ability to protect them from

corrosion - rapidly and effectively. This aspect of shipbuilding, the

surface preparation and subsequent coating of large complex weldments has

been undergoing significant change as modern yards throughout the world

move to new methods of construction.

Work-handling methods have assumed new

importance in an era of high labour costs; but a more rationalised

approach is also needed since stringent specifications now govern the

standards of surface preparation and paint application for optimum

coating life.

To

reach these standards surface protection procedures require that shot

blasting and coating - traditionally outdoor operations - be conducted

indoors, free from the vagaries of the weather. The paint hall provides

for enhanced production performance and to strict blasting and painting

standards.

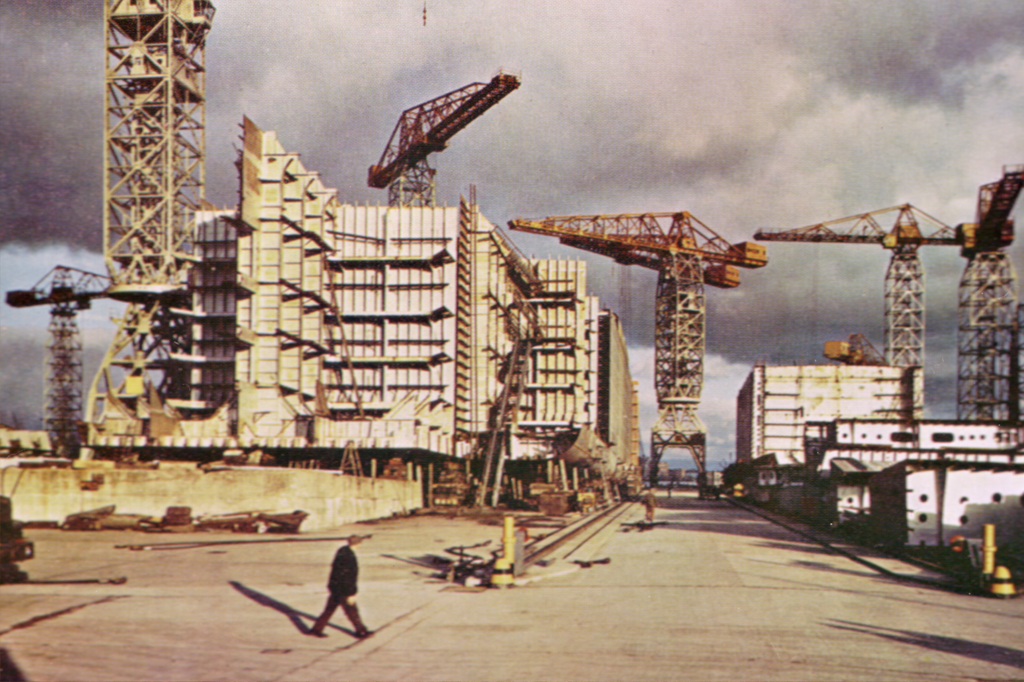

The under-cover painting concept involves the

erection of a paint hail as part of the shipyard's production line.

Containing two or more paint cells, the hall is designed to handle, in

rotation, the surface preparation and Coating of fabricated sections. What

is probably the largest and certainly the most advanced example of this

concept is the multi-million pound paint hall recently completed in the

Belfast shipyard of Harland and Wolff, Limited, for whom Babtie Shaw &

Morion of Glasgow acted as the consulting civil and structural engineers.

Although at Harland and Wolff's yard shotblasting

and priming have been performed under cover for many years the new

facility meets the need for more economic methods of handling and

rationalises the Company's whole approach to the surface protection of

large weldments. Final painting of the ship is, of course, done outdoors.

Weldments up to 500 tonnes are shotblasted to a

predetermined international standard. This is followed by recovery of the spent

abrasive and then by the coating and curing processes. The entire operation is

carried out in dust-free surroundings in which ambient temperatures and

humidity's are controlled in order to meet the requirements of a particular

coating. The building of a modern ship - between 60 000 and 500 000tdw - is a

production line operation and a brief description of Harland & Wolffs steel

facility indicates the scale of operations and the role and purpose of the paint

hall.

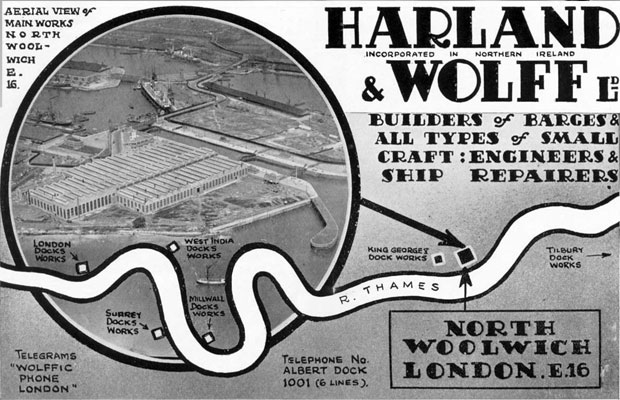

Steel-working facilities

Steel in

standard plates and sections from the unloading quay is stored outside in four

main stockyard bays 245m long by 40m wide, provided with cranes of up to 16 tons

capacity for plates and 7 tons for sections. Buildings in this area house plant

for straightening, shotblasting and priming the plates and sections. Uncut

steel, after straightening, is passed on roller conveyors' through a high

production automatic airless shotblasting machine to remove mill scale. At this

early stage shotblasting poses few of the problems encountered when blasting

fabricated steel. Plates and sections are primed automatically. Blasted and

primed steel is transported to the plate burning shop for culling and edge

preparation and to the section shop for assembly line preparation of sections

for fabrication. Transferred to the panel shop for assembly line production

plates and sections are formed into stiffened panels of up to 240 tons weight.

The plate shop is 150m long and the section and panel shops are each 210m long.

Movement of plates is via a small transfer trolley. Sections travel via a

transverse co-ordinator.

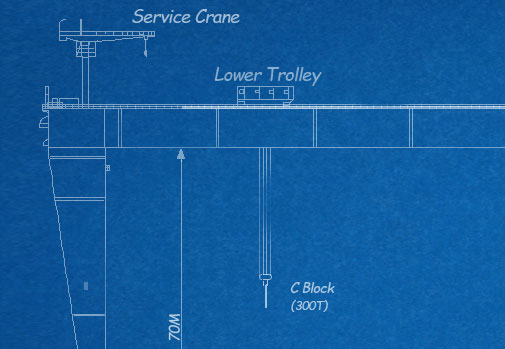

It is in the vast build-up shop, 180m long and 55m

wide with a height to eaves of 355m that ship sections of up to 500 tons in

weight are fabricated. Two 200- tonne and two 40-tonne cranes running on

rails at different levels cover the whole floor area. Large doors 21m high

permit the removal by transporter of the fabricated units to the paint hall.

Paint hall

Here

massive ship sections are sited on stools 2 metres high so that every

surface can be reached for blasting and coating.

Owing to earlier

handling and the welding and fabrication procedures, the weldments on

arrival must be blasted to achieve a surface suitable for application of

either conventional or modern sophisticated coatings. The average

estimated area to be blasted and coated per weldment is 560m , and is

normally accomplished by nine blasting operators. However the Harland and

Wolff paint cells have provision for operating with up to 13 operators.

Abrasive recovery time is reckoned additionally.

In practice all weldments are usually

blasted and painted in the same cell. This is permissible because of the

highly effective means adopted for recovering the spent abrasive and for

dust and paint fume extraction, and desirable because heat would be lost and

the risk of rain damage to the cleaned surface increased 8 tons of grit per

hour per unit. Each integrated Munkebo unit consists of two pumps and two

cyclone separator - collectors to remove dust and oversize particles.

Separated steel grit is delivered for re-use via the silos through a

vibratory air wash cleaner to storage hoppers, each of which is capable of

feeding five blast machines. Suction pick-up hoses and self-propelled cars

are employed for initial retrieval.

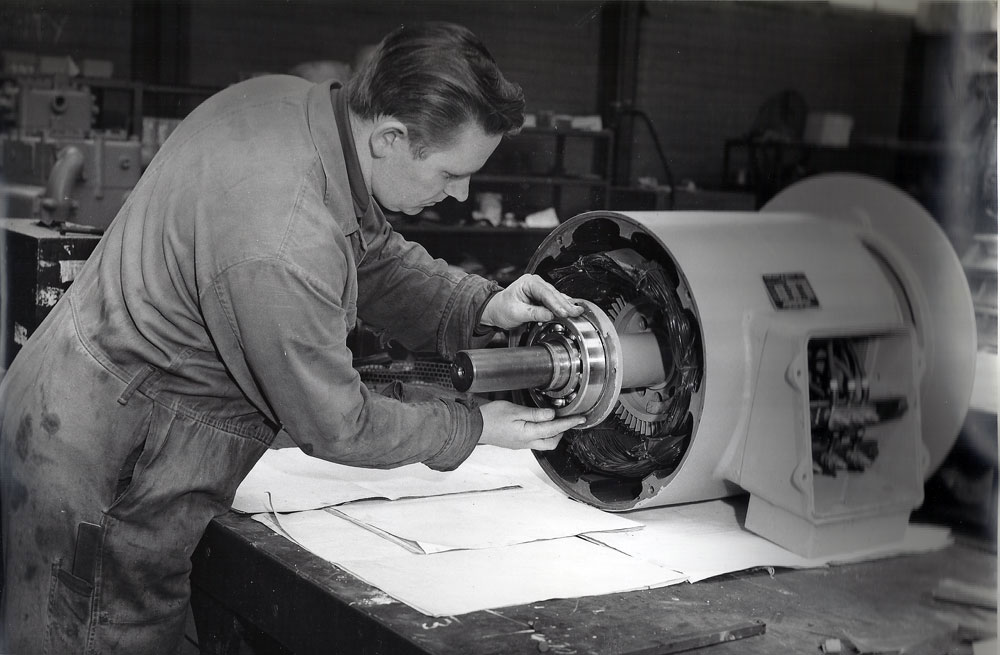

Heating,

ventilation, dust extraction, cleaning and painting

As

the primary purpose of dust extraction is to provide optimum operator

visibility a high rate of extraction is essential. High efficiency

extraction is also required to remove paint fumes. The advanced

ventilation and dust separation equipment demanded by the three operations

of blasting, painting and curing has been supplied by AB Bahco Ventilation

of Enkoping, Sweden. The firm has also supplied the plant through which

heated air enters the paint cell at ceiling level and is blown down to

floor level. Polluted air is extracted through wall vents close to the

floor. After cleaning, by scrubbing, it is vented to the atmosphere.

The Bahco cascade scrubbers installed in the main central corridor

operate on the principle of wet separation, using the impact of nigh

velocity air on liquid to create intense turbulence and droplet

dispersion. The dust-laden air is cleaned by intimate contact with the

liquid and the separated dust in the form of a sludge is collected for

disposal. Coatings are applied by the airless spray method. Six

wall-mounted 47:1 ratio pumps are allocated to each cell.

Additionally, and stored in the annexe, are six portable pumps with paint

mix and cleaning equipment.

Services and amenities

The Harland and Wolff paint hall includes suspended work platforms - six

electrically-operated platforms per cell with push button control;

compressed air system fed by four air compressors with outputs of 64m3/min

each al 8kg/cm2; fire protection system - the complete building is

monitored by flame smoke arid gas detectors; control room, and an amenity

annexe with lockers, showers and rest rooms for a 30-man shift.

Thus grouped under cover are the services and the essential equipment

needed for a high standard of surface protection a facility that is rapid,

effective and continuously available whatever the external circumstances.

The paint hall complex now nearing completion at Harland & Wolff's yard

sets the pattern of future developments in progressive shipbuilding yards

elsewhere.

Since 2007 the Paint Hall has been reinvented as "The Titanic

Studios". At 110,000 sq ft it is one of Europe’s largest film studios.

Attracting producers such as HBO, Universal and Playtone, the set has

welcomed international productions including ‘Game of Thrones’, ‘Your

Highness’ and ‘City of Ember’.

|

|

The PartnersHarland, Wolff, Pirrie and Wilson

The PartnersHarland, Wolff, Pirrie and Wilson

The HatsChairmen, MD's, CEO's

The HatsChairmen, MD's, CEO's

Sir Frederick RebbeckChairman 1930-41 1944-62

Sir Frederick RebbeckChairman 1930-41 1944-62

Sir Charles PalmourChairman 1941-1944

Sir Charles PalmourChairman 1941-1944

John S BallieChairman 1962-1965

John S BallieChairman 1962-1965

Dr Dennis RebbeckChairman 1965-1966

Dr Dennis RebbeckChairman 1965-1966

Sir John MallabarChairman 1966-1970

Sir John MallabarChairman 1966-1970

Joe R EdwardsChairman 1970

Joe R EdwardsChairman 1970

Alan WattActing Chairman 1970-1971

Alan WattActing Chairman 1970-1971

Lord RochdaleChairman 1971- 1975

Lord RochdaleChairman 1971- 1975

Sir Brian MortonChairman 1975-1980

Sir Brian MortonChairman 1975-1980

Victor Alexander CookeChairman 1980-1981)

Victor Alexander CookeChairman 1980-1981)

Vivian WadsworthChairman 1981-1982

Vivian WadsworthChairman 1981-1982

Sir John ParkerChairman 1982-1992

Sir John ParkerChairman 1982-1992

Islandmen(and Women)

Islandmen(and Women)

Save our ShipyardSupport and solidarity

Save our ShipyardSupport and solidarity

The War MemorialsWe Will Remember Them

The War MemorialsWe Will Remember Them

The Bible Class

The Bible Class

Nicknames

Nicknames

The Yarns(and Tall Tales)

The Yarns(and Tall Tales)

The Shipyard IndentureJW Mullholland

The Shipyard IndentureJW Mullholland